Introduction

In the realm of customized clothing, one of the most common questions newcomers have is What is silk screening for T-shirts ? and the reason it is among the top printing methods in the present. If you’re setting up a clothing company, designing your own custom merchandise, or are interested in how printed t-shirts are created, silk screening – also called screen printing, plays an important part in the design of high-end apparel.

This article explains the essential information you should learn about the process of silkscreen printing and what it is that makes it unique and the technology involved and how businesses continue to rely on it well into 2025. We’ll dive into.

What Is Silk Screening for T-Shirts?

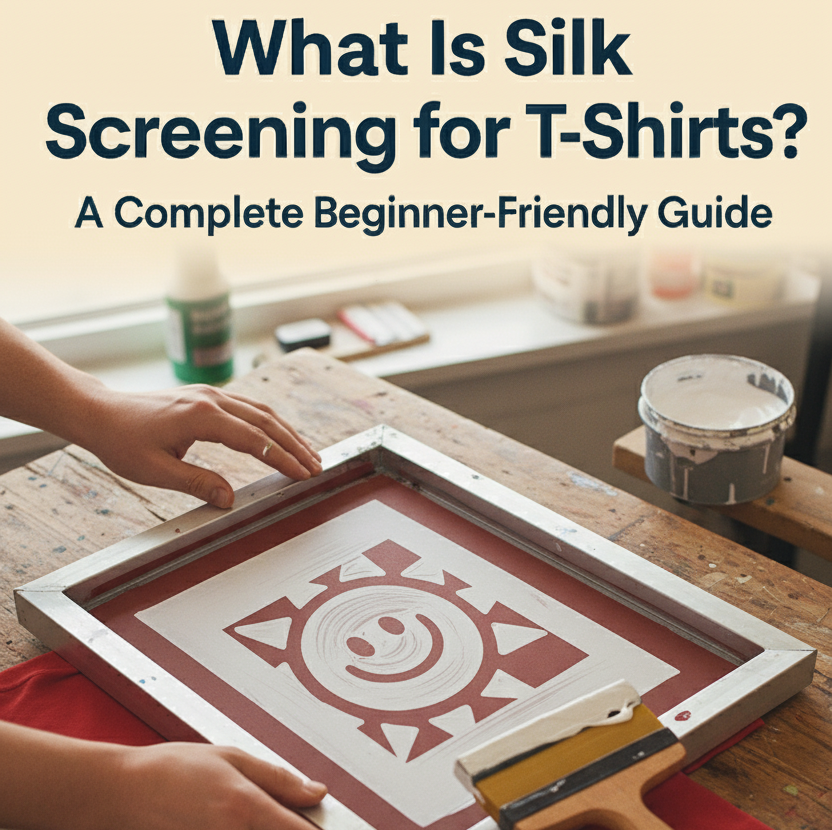

Silk screening in t-shirts the method of printing where ink is forced through the mesh screen onto the fabric to make an image. Silk fabric was used for the screen, hence its name “silk screen”–but now, the use of polyester mesh has become more popular.

Screen printing is known for its high-quality, durable prints that last for a long time specifically for large orders. If you’ve ever wore the highest-quality graphic t-shirt that has bright colors, odds are the garment was created with screen printing.

How Silk Screening Works (Simple Step-by-Step)

1. Designing the Artwork

The artwork is designed in digital form using programs such as Adobe Illustrator or CorelDRAW. Vector art is the best choice since it is easy to scale.

2. Making the Screen

The mesh screen is coated with the lightweight emulsion.

The image’s black-and-white versions are set on top while the screen is then exposed to light from UV.

Where the image blocks illumination, the emulsion is in a soft state and then is washed away creating an opening for ink to flow through.

3. Setting Up the Screen on the Press

The screen connects to a press.

Each color within the design needs an individual screen and this is the reason why prints with multiple colors take longer.

4. Applying the Ink

Ink (usually water-based or plastisol ink) is then poured on the mesh.

A squeegee is employed to push the ink across the mesh before it is poured onto the shirt.

5. Curing the Print

Following printing, the shirts pass through a heated dryer to cure the print.

Proper curing guarantees that the printed image is durable, resistant to cracks, and wash-safe.

Why Silk Screening Is Popular for T-Shirts

1. Extreme Durability

Silk-screened prints be used for 100+ washes without fade.

The ink can be seen as a part of the fabric.

2. Vibrant Colors

Screen printing employs large amounts of ink which give vivid and vibrant outcomes.

This makes perfect for graphic t-shirts, logos as well as retail items.

3. Cost-Effective for Bulk Orders

It’s a lot of work however, when it’s completed, printing hundreds of shirts gets cheap and quick — making bulk t-shirt printing very efficient.

4. Works on Most Fabrics

Polyester, cotton, and blends — screen printing manages the entire spectrum with ease.

5. Perfect for Large Designs

Back prints, chest prints, prints that are large — silkscreen is able to handle them with ease.

When Should You Choose Silk Screening?

Silk screening is a fantastic alternative when:

It is essential to have top-quality, custom-designed t-shirts to promote your company, brand or for company

Your design uses 1–4 solid colors

Printing in bulk amounts (20–1000+ T-shirts)

You’re looking for lasting, high-end prints with professional quality

If you’re looking to get full-color picture print, DTG may be the best choice. However, for bold graphic printing, screen printing is always the best option.

Common FAQs About Silk Screening

1. Is silk screening expensive?

It is more laborious to set up so small orders may cost a lot. But, for bigger quantities the cost can become very reasonable.

2. How long will silk-screened shirts last?

If they are properly cared for, they can last for a long time or even 100+ washes, without breaking or fading.

3. Can silk screening print detailed designs?

Yes, modern screens allow high-resolution images however, images that are photo-realistic could require different printing techniques.

Final Thoughts

In the end if you’re asking about silk screening for T-shirts, it’s among the most secure and efficient methods to produce durable, high-quality printed garments. The durability, high-quality, and cost-effectiveness make it the best choice for custom-designed projects and brands.

About US

Rise Digitizing offers top-tier embroidery digitizing, vector art services, and customized patches for clothing and brand creators. Rapid delivery times and top-quality results have made them a reliable supplier to embroidery and printing enterprises across the world.