If you are looking for bold and long-lasting designs for your fabric, screen printing is the most effective method to use. This article explains the process of What is screen printing t shirts, as well as the reason why many ask what is silk screening for t shirts, and outlines the steps on how to make screen print tees — all in one place.

Introduction

If you’ve ever thought about how screen printing works on T-shirts, you’re not by yourself. Screen printing is the most popular method employed by artists, brands, and merch manufacturers to print high-quality, durable designs on clothing. In this article, you’ll understand how it’s done, what terms (including the silk screen) mean, the advantages and disadvantages, and an easy DIY method you can test at home to make professional-looking tees.

What is Screen Printing T Shirts?

What is screen printing t shirts?

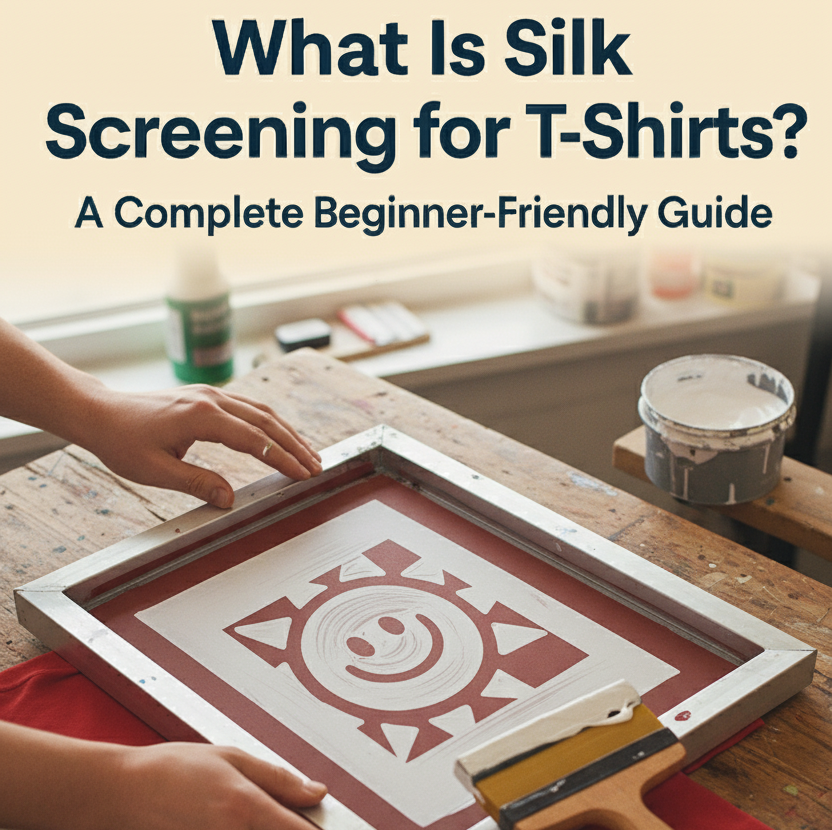

It refers to a printing process that transfers ink across the fine mesh of a screen onto fabric using stencils. Every color of a pattern requires its own screen. The ink gets pushed across the mesh using a squeegee, layer after layer, until the entire design is visible. After printing, the ink must be dried (usually using heat), which causes it to adhere to the fabric and become wash-stable.

The Advantages of Screen Printing on T-Shirts:

Prints with high durability that endure through numerous washes.

Colors that are opaque, vibrant, and vivid — particularly on dark-colored fabrics.

Cost-effective for medium and large runs.

Can be used on a variety of materials, including blends, cotton, and certain synthetics.

What Is Silk Screening for T Shirts?

Many ask why silk screening is used for printing t-shirts. The short answer is that what is silk screening for t shirts uses exactly the same process as screen printing. The term “silk screening” comes from the first screens that were created using silk. Modern screens are constructed from polyester meshes (like polyester), but the old term remains.

If you ask about silk screening for t shirts, know that it refers to the same trusted method artists and printers use to produce bold, durable clothing graphics.

The Screen Printing Process (Simple Breakdown)

Learning the right steps can help when trying to understand how to make screen print tees or when working with an expert printer.

1. Design Preparation

Design your artwork, then separate the color layers.

2. Screen Design

Coat the screen with a light-sensitive emulsion, then place a transparent image on it and expose it to light. The exposed emulsion hardens; the unexposed emulsion is washed away, leaving the design.

3. Setup

Mount the screen onto the press and align it with the top of the t-shirt.

4. Printing Application

Ink is poured toward the upper area of the screen, then a squeegee is used to push ink across the mesh and onto the shirt.

5. Curing

Use a heat source (dryer or heat press) to set the ink so it won’t wash away.

6. Quality Test

Examine for alignment, bleeding, and color consistency.

When printing with multiple colors, you must repeat the inking and curing process for each screen or color.

How to Make Screen Print Tees (Beginner DIY)

If you’re interested in trying to make screen print tees at home, here’s a secure and simple method to get started:

Materials Needed:

Blank t-shirts (pre-washed)

Mesh screen printing frame

Photo emulsion + sensitizer

Transparent film with your design (printed in black)

Screen printing ink (plastisol or water-based)

Squeegee

Light source for exposure (sunlight works fine)

Heat gun, hair dryer, or heat press for curing

Steps:

Cover the screen evenly with emulsion in a dim room. Let it dry.

Place your transparency on the screen and expose it to light per the emulsion instructions.

Wash out the unexposed emulsion to reveal your stencil.

Position the shirt and secure the screen in place.

Apply ink along the top of the screen and push it across the stencil with firm, even pressure.

Lift the screen and inspect the print. Repeat if necessary.

Cure the ink with heat until the design is permanent.

Advantages & Limitations

Benefits of Screen Printing T Shirts:

Best for bulk orders (low per-unit cost when scaled).

Outstanding color opacity and durability.

Wide range of specialty inks and finishes (metallics, puff, discharge).

Limitations:

Not ideal for highly detailed photo-realistic prints (DTG might be better).

Setup time and screen costs make small orders pricier per shirt.

Multi-color designs require precise registration.

Pro Tips for Better Prints

Always pre-wash garments to remove chemicals and sizing.

Use proper mesh count screens based on design detail. (Lower mesh = more ink, higher mesh = finer detail.)

Keep screens clean and store them flat.

Check curing time and temperature for your specific fabric and ink type.

Final Thoughts

Knowing what is screen printing t shirts and understanding what is silk screening for t shirts gives you a solid foundation to decide whether to DIY or hire a pro.

If you’re curious about how to make screen print tees, start small, practice the basics, and scale up once you’ve mastered registration and curing. Screen printing requires patience, but with time and consistency, you’ll create vibrant, durable T-shirts that look professional and feel great to wear.

You can also use our Custom Screen Printing in USA, we specialize in embroidery digitizing and vector art services that complement your screen printing projects. Whether you need sharp vector files or digitized designs for apparel, Rise Digitizing ensures your creative ideas are production-ready and print perfectly every time.