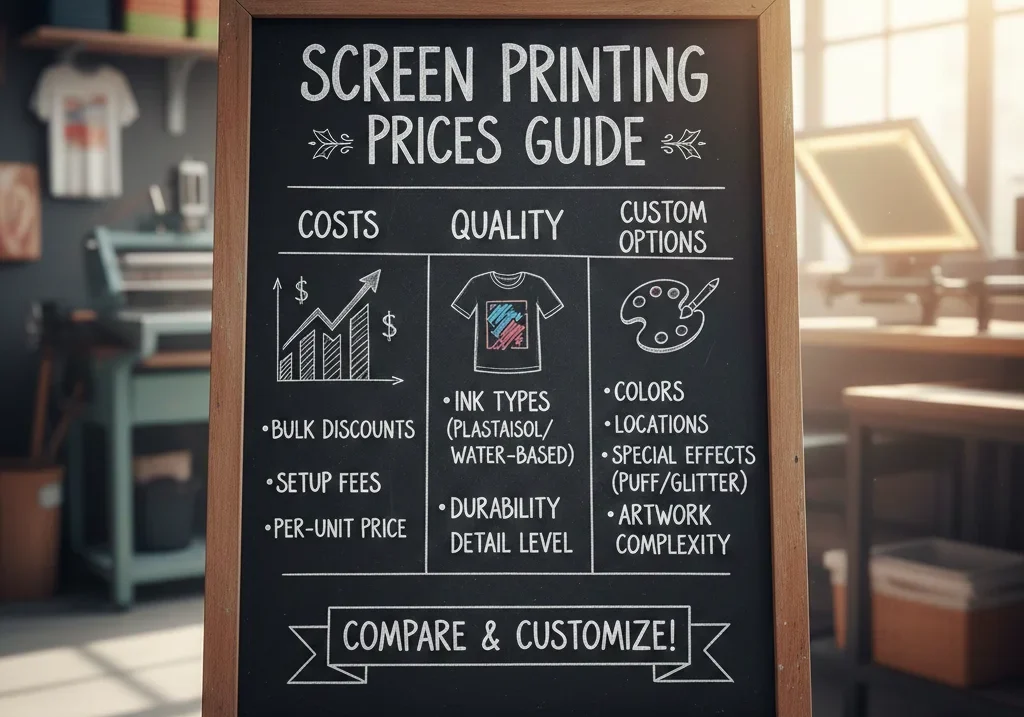

Screen printing is one of the most popular and reliable printing methods for custom apparel, merchandise, and promotional items. Whether you’re a small business owner, event organizer, or clothing brand, understanding screen printing prices helps you plan your budget, compare vendors, and get the best value for your order.

In this complete guide, you’ll learn how pricing works, what affects the total cost, and how to choose the right quality and customization options for your project.

Introduction to Screen Printing Costs

Screen printing offers vibrant colors, long-lasting prints, and excellent value for bulk orders. But the pricing can be confusing for beginners because it isn’t a simple flat rate. Instead, screen printing prices depend on several variables such as the number of colors, quantity, fabric type, and print placement.

This guide breaks down each factor to help you understand what you’re paying for—and how to reduce costs without compromising quality.

1. What Affects Screen Printing Prices?

Here are the major elements that determine the overall cost of your screen printing order:

➤ 1. Number of Colors in the Design

Each color requires a separate screen, which increases setup costs.

- Single-color prints → cheaper

- Multi-color prints → higher cost due to multiple screens

- Full-color graphics → may require special techniques

Tip: For budget-friendly printing, keep your design simple with fewer colors.

➤ 2. Quantity of Items Ordered

Screen printing becomes cheaper as your order size increases. This is because setup costs spread across more items.

- Small orders (1–24 pieces) → higher per-unit cost

- Medium orders (25–100 pieces) → moderate pricing

- Large orders (100+ pieces) → lowest per-unit cost

Bulk ordering offers the best value.

➤ 3. Type of Garment or Material

The price also depends on what type of item you’re printing on:

- Cotton T-shirts → cheapest option

- Performance/Polyester shirts → slightly higher

- Hoodies & sweatshirts → more expensive due to thicker fabric

- Tote bags, aprons, jackets → specialty pricing

Premium brands (Bella+Canvas, Gildan Softstyle, Next Level, etc.) cost more.

➤ 4. Print Size & Placement

Larger print areas require more ink and more time.

Common print placements include:

- Full front

- Left chest

- Full back

- Sleeves

- Inside tag area

A larger area or multiple placements increases the cost.

➤ 5. Type of Ink Used

Different inks have different costs depending on effects and finish.

Common options:

- Standard plastisol → most affordable and durable

- Water-based ink → eco-friendly but pricier

- Discharge ink → soft feel, higher cost

- Metallic or glitter → special effect pricing

- Puff or 3D ink → premium pricing

If you want a unique look or feel, expect a higher price.

➤ 6. Specialty Add-ons

Additional features can also affect your screen printing price:

- Custom neck labels

- Individual folding or bagging

- Expedited printing

- Color matching (PMS matching)

- Foil, reflective, or glow-in-the-dark

These upgrades add extra cost but increase the overall presentation value.

2. Average Screen Printing Prices (General Estimates)

While exact pricing varies by vendor, these are typical costs in the industry:

Setup Costs

- Screen setup fee: $15–$35 per color

- Design or artwork prep fee: $10–$50 (if required)

Per-Shirt Costs Based on Quantity

| Quantity | 1 Color | 2 Colors | 3 Colors |

|---|---|---|---|

| 12 pcs | $12–$18 each | $14–$20 | $16–$22 |

| 50 pcs | $6–$10 each | $7–$12 | $8–$14 |

| 100+ pcs | $4–$8 each | $5–$9 | $6–$10 |

These prices may vary depending on garment type and print size.

3. Bulk Ordering: Why It Saves Money

If you’re printing for an event, brand launch, or team, ordering more pieces dramatically reduces the per-item cost because:

- Screens are already made

- Ink usage cost is minimal

- Labor stays the same

The more you order, the cheaper each printed item becomes. This makes screen printing an excellent option for:

- Clothing brands

- Sports teams

- Company uniforms

- Giveaways

- Festivals and events

4. How to Reduce Screen Printing Prices

If you’re working on a tight budget, here are practical ways to save:

✔ Limit your design to 1–2 colors

This reduces screen fees and printing time.

✔ Choose standard garments

Basic cotton tees are cheaper than premium fabrics.

✔ Use one print location

Front or back only instead of multiple placements.

✔ Increase your quantity

Bulk orders lower the per-piece cost significantly.

✔ Provide print-ready artwork

This avoids additional design charges.

5. Screen Printing vs. Other Printing Methods (Cost Comparison)

| Method | Best For | Cost Advantage |

|---|---|---|

| Screen Printing | Bulk orders | Lowest cost per piece in large quantities |

| DTG (Direct-to-Garment) | Small orders, full color | No screen fees, but higher per item |

| Heat Transfer Vinyl | Personalization | Affordable for small runs and custom names |

| Sublimation | Polyester items | Great for all-over prints but limited fabric types |

Screen printing remains the most cost-effective choice for bulk apparel printing.

6. Choosing the Right Screen Printing Service

When comparing printers, focus on:

- Print quality

- Pricing transparency

- Turnaround time

- Customer reviews

- Ink options and artwork support

Request a sample or proof before finalizing your order to ensure quality matches your expectations.

Conclusion

Understanding screen printing prices helps you plan better and avoid unexpected costs. Factors like design complexity, garment type, ink choice, and order quantity all play a role in determining the final price.

By choosing the right options and optimizing your design, you can get high-quality prints that fit your budget. Whether you’re printing for business, branding, or personal use, screen printing remains one of the most durable, vibrant, and cost-effective printing methods available.

FAQs

1. Why does screen printing have setup fees?

Because each color in your design requires a unique screen, setup fees cover the labor and materials needed to prepare these screens before printing begins.

2. Is screen printing cheaper than DTG?

Yes—screen printing is usually cheaper for medium to large orders. DTG is better for small orders or complex, full-color artwork.

3. How can I lower the cost of screen printing?

Simplify your design, use fewer colors, choose a basic garment, and increase your order size to reduce per-unit pricing.

About Us

For high-quality embroidery digitizing services, Rise Digitizing delivers fast, accurate, and affordable solutions.

If you need custom digitizing for patches, caps, shirts, or logos, Rise Digitizing is always ready to help.